Aluminium Alloy 6061-T651 Aluminium Phaj

Khoom Taw Qhia

Hom 6061 txhuas yog ib qho ntawm feem ntau siv txhuas alloys. Nws lub peev xwm weld-muaj peev xwm thiab formability ua rau nws haum rau ntau yam kev siv hom phiaj. Nws lub zog siab thiab corrosion kuj qiv hom 6061 alloy tshwj xeeb tshaj yog muaj txiaj ntsig hauv aviation, Marine, tsheb tsav, kev sib txuas lus hluav taws xob, semiconductors, hlau pwm, fixtures, mechanical equipment and parts and other fields.

Cov ntaub ntawv kev lag luam

| MODEL NO. | TIAB SA 6061-T651 |

| Thickness xaiv tau ntau yam (mm) (ntev & dav tuaj yeem xav tau) | (1-400) hli |

| Nqe ib KG | Kev sib tham |

| MOQ | ≥1KG |

| Ntim | Txheem Hiav Txwv Tsim Nyog Ntim |

| Lub sij hawm xa tuaj | Tsis pub dhau (3-15) hnub thaum tso kev txiav txim |

| Cov ntsiab lus ua lag luam | FOB / EXW / FCA, thiab lwm yam (tuaj yeem sib tham) |

| Cov nqe lus them nqi | TT / LC; |

| Daim ntawv pov thawj | ISO 9001, thiab lwm yam. |

| Qhov Chaw Keeb Kwm | Tuam Tshoj |

| Cov qauv | Cov qauv tuaj yeem muab rau cov neeg siv khoom dawb, tab sis yuav tsum yog cov khoom thauj khoom. |

Chemical Component

Si (0.4% - 0.8%); Fe (0.7%); Cu (0.15% - 0.4%); Mn (0.15%); mg (0.8% - 1.2%); Cr (0.04% - 0.35%); Zn(0.25%); Ai (96.15% -97.5%)

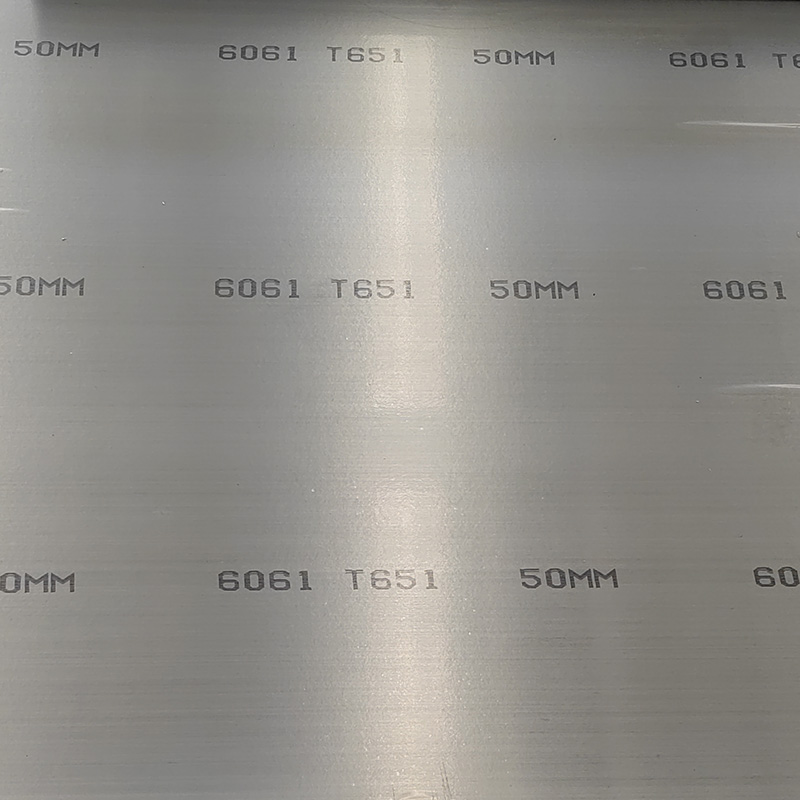

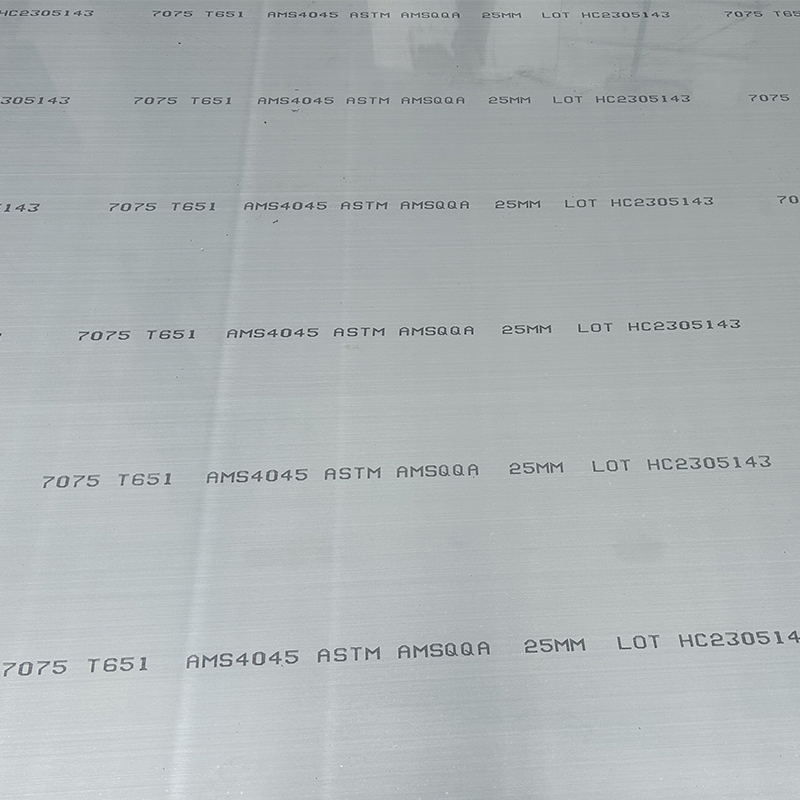

Cov duab khoom

Cov ntaub ntawv ua haujlwm ntawm lub cev

Thermal Expansion (20-100 ℃): 23.6;

Melting Point (℃): 580-650;

Hluav taws xob conductivity 20 ℃ (% IACS): 43;

Hluav taws xob tsis kam 20 ℃ Ω mm² / m: 0.040;

Qhov ceev (20 ℃) (g / cm³): 2.8.

Mechanical nta

Qhov kawg Tensile zog (25 ℃ MPa): 310;

Tawm Zog (25 ℃ MPa): 276;

Hardness 500kg / 10mm: 95;

Elongation 1.6mm (1/16in.) 12;

Daim ntawv thov teb

Aviation, Marine, tsheb tsav, hluav taws xob sib txuas lus, semiconductors,hlau pwm, fixtures, mechanical equipment and parts and other fields.